Thermal management in electric and hybrid vehicles is becoming increasingly important. UFI Filters is already prepared for this challenge by offering a wide range of dedicated products to meet the needs of all types of vehicles

The thermal management of vehicle components is set to play an increasingly important role with the spread of hybrid and electric propulsion. Today’s most popular batteries, which base their technology on lithium-ion, work optimally if they are kept at a temperature range between 15 °C and 35 °C.

Thermal management devices have the essential function of maintaining temperatures within this range, cooling or heating the battery and thus preventing it from losing efficiency or posing a safety risk.

Thermal management is also able to ‘take’ heat where it is developed in a vehicle (e.g. in the transmission) and channel it to where it is needed, taking over functions such as heating the passenger compartment without the need to use energy from the battery.

A dedicated Business Unit

Aware of the importance that this sector is set to assume in the near future, UFI Filters, since 2010, has expanded its activities beyond the field of filtration systems. For this reason, it created a new business unit dedicated to thermal management systems in 2022.

The division enjoys the benefits of working with a dedicated R&D team based at the UFI Filters Group’s Innovation Centre in Ala di Trento. The aim is to rapidly devise and implement technological innovations for the changing phase of the automotive industry.

In the thermal management sector, UFI Filters is very active in the field of heat exchangers, supplied as original equipment to automotive manufacturers since 2010, and heat pumps.

UFI Filters heat exchangers are made of aluminium using the special vacuum brazing technique which results in stronger, more efficient and cleaner components than traditional steel systems.

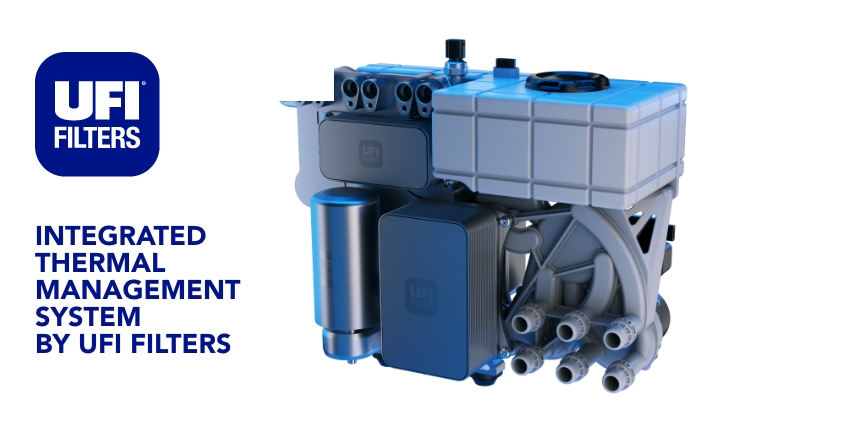

The UFI Group‘s seven dedicated thermal management product lines cover the needs of vehicles of all types.

These are heat exchangers for engine and transmission oil (for vehicles with internal combustion engines, or hybrids), heat exchangers for transmission oil, liquid-cooled condensers (suitable for vehicles with combustion engines as well as hybrid and electric vehicles), chillers and heaters for battery liquids, coolant flow valves (for hybrid and electric vehicles), and heat exchangers for e-axles of electric vehicles.

Premium applications

The excellence achieved in thermal management means that UFI Filters supplies the transmission oil cooling system for Audi and Porsche‘s PPEs (Premium Electric Platforms) for mid- to high-end models such as the Porsche Macan EV and the Audi Q6 e-tron, including Avant, Sportback and RS versions.

There are two UFI coolers on these cars, one dedicated to the front and one to the rear electric motor drive. Their task is to keep the transmission oil temperature within optimum values, even when high performance is required. UFI thermal management systems are produced at the Opole plant in Poland.

UFI Filters has also developed thermal management systems for heavy-duty vehicles, such as the multi-heat exchanger for transmission oil developed for Daimler Truck AG‘s electric truck, the first zero-emission truck produced in the series. This module consists of two pairs of heat exchangers operating in parallel, assembled in a single aluminium body. Manufactured using vacuum brazing technology, the module ensures perfect interaction with the transmission circuit, optimising the oil temperature in the circuit.

These are just a few examples of the applications of thermal management systems developed by UFI Filters for the automotive sector. Innovative technologies that we will be going into in more detail in the near future, such as heat exchangers and heat pumps.