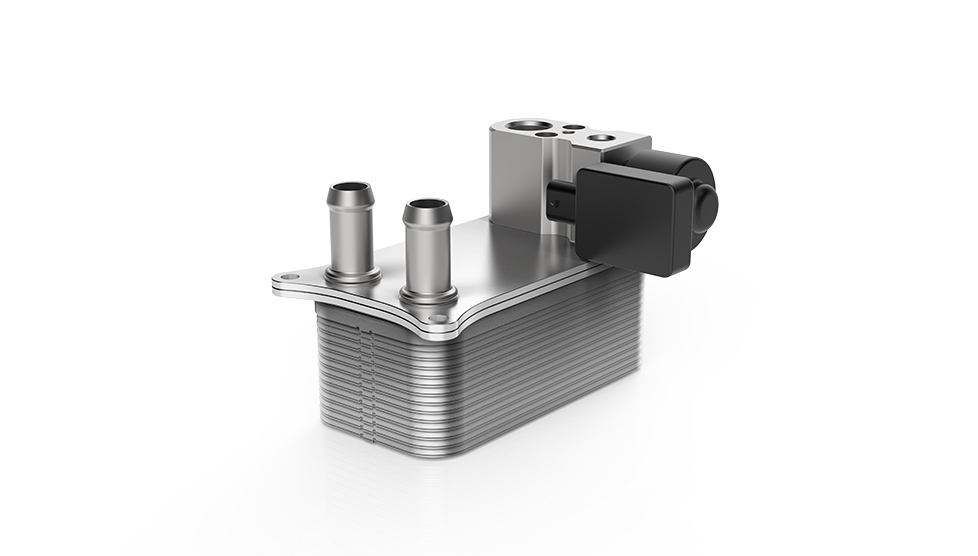

The UFI Filters Group has been present in the world of heat exchangers for the OEM automotive sector since 2010.

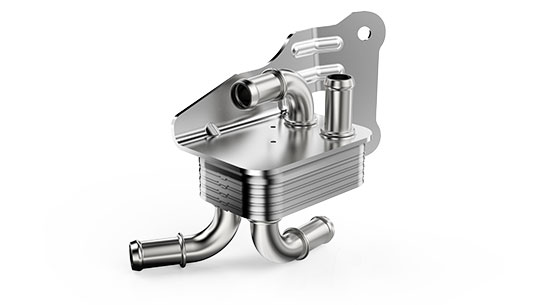

In particular, investment in research and innovation has led to specialisation in the design, development and production of water-cooled and vacuum-brazed aluminium heat exchangers which allow a more robust, efficient and clean product to be achieved

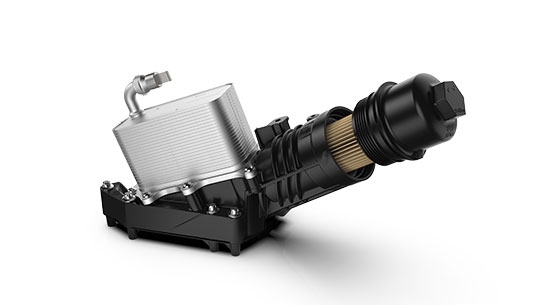

UFI Filters currently provides 7 product lines for thermal management.