In recent years, we are witnessing an increasing spread of electric vehicles, driven in part by the EU’s decision to ban the sale of cars with internal combustion engines from 2035. A decision that is still subject to revision, but which nevertheless outlines a clear direction, so much so that in 2023 more than two million electric cars were sold in Europe.

Almost all current electric vehicles are equipped with lithium-ion batteries, which offer a high energy density and deliver the considerable amount of current needed to run the electric motors.

However, this technology also presents some critical issues, mainly related to the operating temperatures of the cells. Their optimal operation is guaranteed if the values remain in a range between 15 and 35 °C. Above and below this range, a deterioration in battery performance and safety problems can occur. One of the greatest risks is the so-called ‘thermal runaway’, a phenomenon of progressive overheating of an increasing number of cells which, in the most serious cases, can lead to a vehicle fire.

This explains why on electric cars, as well as hybrids, a Thermal Management System, i.e. a device that monitors and manages battery temperatures, is essential. This ensures that they always remain within the correct operating range. A function that will remain essential in the future, when batteries of different technologies are adopted, for example those with solid electrolyte instead of liquid, which are currently in the experimental phase.

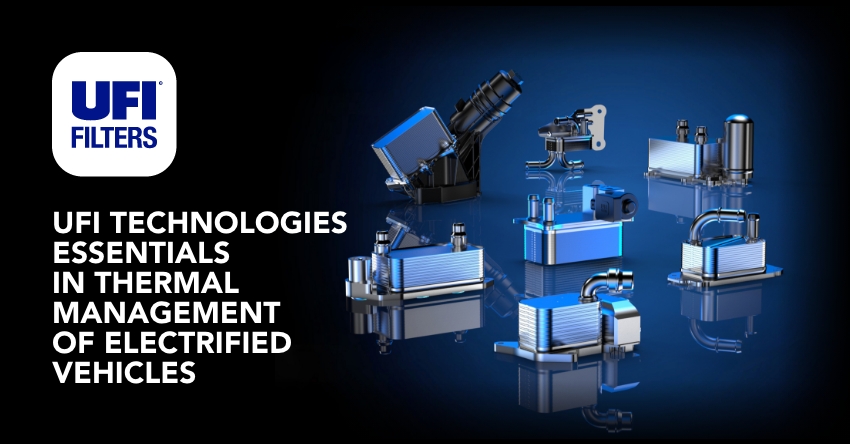

A complete range

UFI Filters, aware of the ever-increasing importance that these components will have in the coming years, created its own Business Unit dedicated to Thermal Management systems in 2022. Present in the original equipment heat exchanger sector since 2010, UFI Filters has specialised in the design, development and manufacture of aluminium heat exchangers, produced using the vacuum brazing technique.

This process makes it possible to obtain an all-aluminum product by superimposing the plates in a vacuum furnace that avoids the risk of oxygenation, making it unnecessary to add other materials, which are necessary in the open furnace method. The exchanger thus obtained is lighter, more efficient and cleaner than traditional steel systems.

Today, UFI Filters offers seven product lines dedicated to the thermal management of electric, hybrid and combustion engine vehicles. Suitable for propulsion systems of all types (thermal, hybrid and electric) are transmission oil coolers and liquid-cooled condensers.

Intended only for vehicles with combustion engines are engine oil coolers; for hybrid and electric vehicles, coolant flow valves, which change the coolant path according to the thermal needs of the battery, electric motors, e-axles and power electronics; battery chillers and coolant coolant heater, which are essential for keeping battery pack temperatures under control according to its operating conditions.

Lastly, e-axle heat exchangers, units that integrate electric motor, transmission, inverter and control electronics in a single structure, are dedicated to electric vehicles only.

Heat exchangers for e-axles play a key role in optimising transmission and engine temperatures. In addition, they ensure the connection to the rest of the cooling system.

UFI Filters can supply EV manufacturers with both the individual heat exchanger and the complete module, which integrates the oil filtration, thermal management and oil recirculation functions of the EV transmission.

For original equipment

The excellence of the thermal management systems means that UFI Filters supplies them as original equipment to the world’s largest vehicle manufacturers. For example, Renault, for the 160 kW ePT-160 front-mounted electric motor in the Mégane E-Tech, and Nissan, which will also have a second heat exchanger for the rear-mounted electric motor in the all-wheel-drive version of the Ariya, will be using UFI Filters heat exchangers from 2022.

Alfa Romeo, too, chose UFI Filters thermal management systems for the original equipment of the mild and plug-in hybrid versions of the Tonale SUV, while Chinese high-performance electric car manufacturer NIO awarded UFI Filters the design of the cooler for the e-axle of a new electric vehicle.

Finally, Audi and Porsche have adopted UFI Filters’ transmission oil cooling system for their new Premium Electric Platforms (PPE) for high-end models such as the A6 e-tron, Q6 e-tron and Macan EV.

The thermal management product range, which also includes heat pumps to which we will devote the next in-depth discussion, therefore puts UFI Filters in an optimal position to face the ongoing changes in the world of mobility from a competitive position.